KHOSLA MACHINES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KHOSLA MACHINES P.LTD.

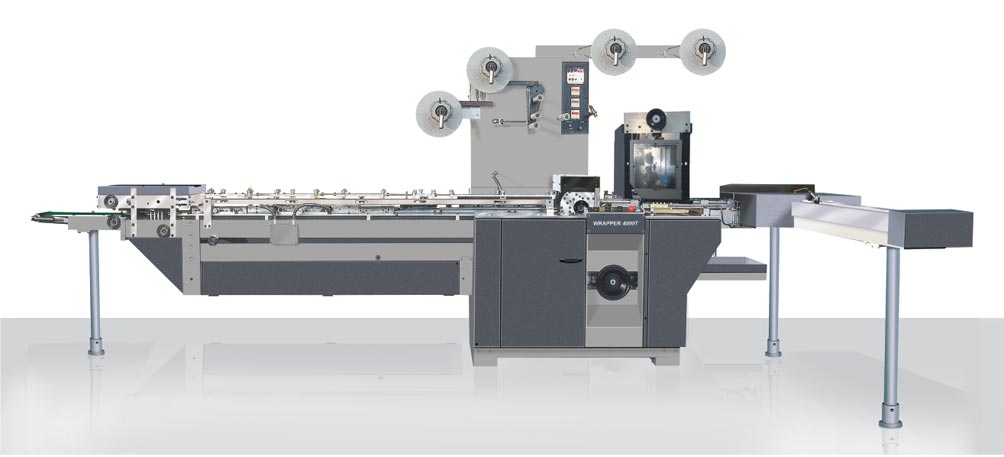

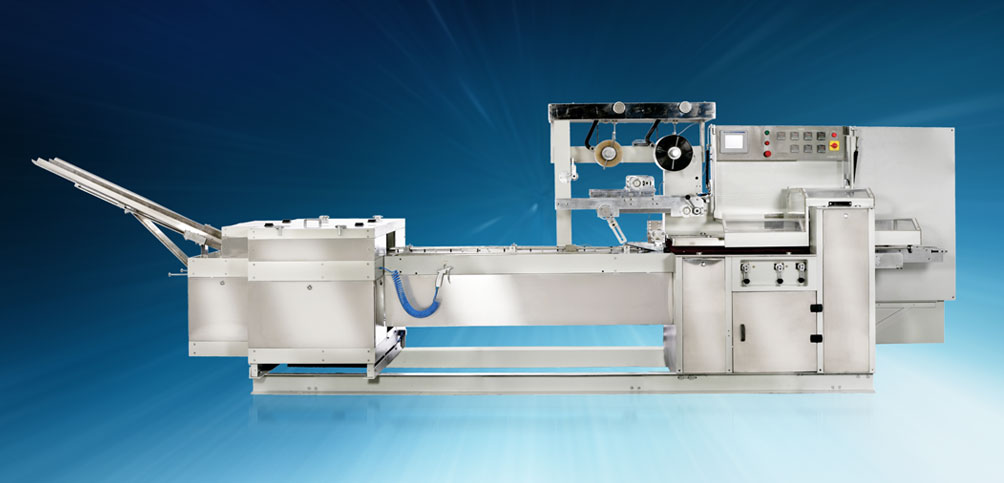

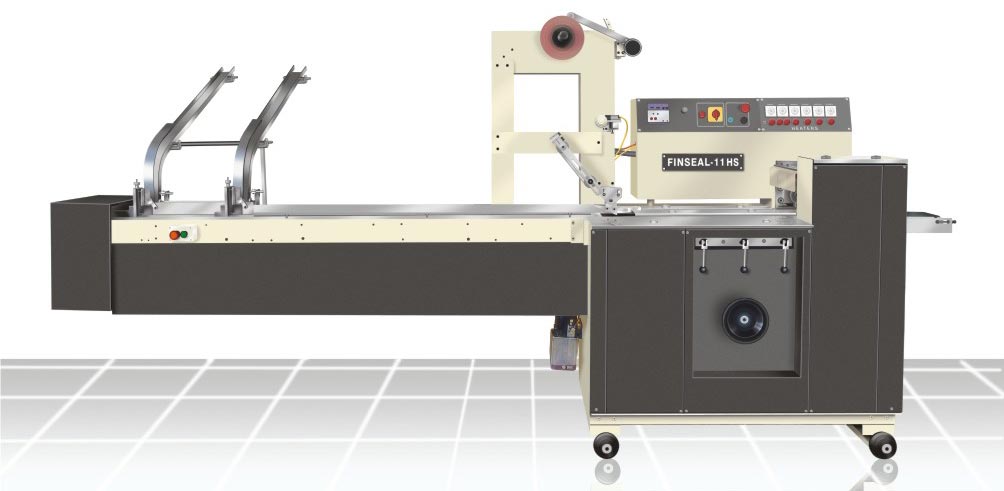

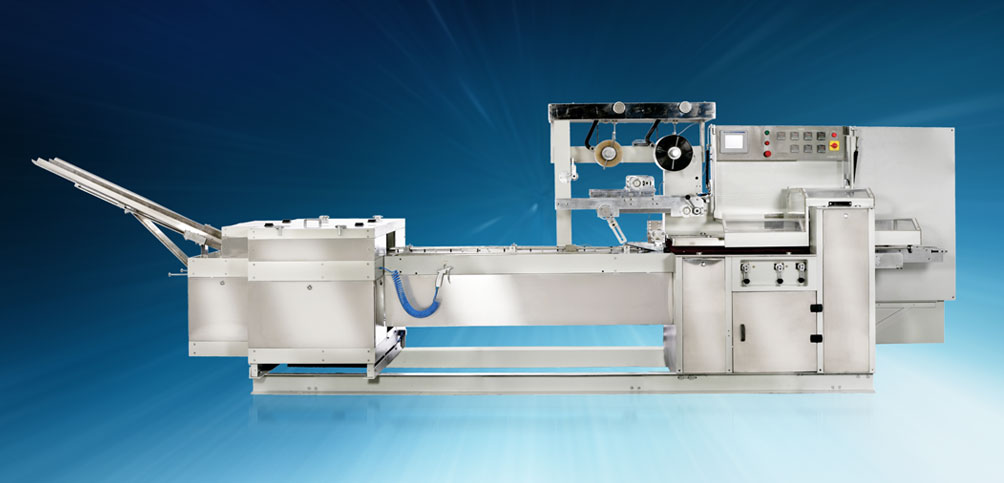

Form Fill And Seal Machine For Biscuits

STANDARD FEATURES

» EASY, QUICK AND FOOL PROOF CHANGE OVER

Logipac 51E uses multiple axes servo control for timing the machine. All the machine timings after the optimization can be stored as a receipe for that size and can be quickly recalled whenever machine has to be set for that size. A few position settings that need to be done manually are simple and can be marked on graduated scale.

» NO - PACKET - NO WRAP INTERLOCK

In a slug packing machine many times a slug is taken off the infeed conveyor for quality reason. If the wrapper keeps flowing continuously it results into empty pack which is counted as wastage. Logipac 51E has a feature to stop wrapper for empty infeed cycle that would have got wasted.

» OPTIONS FOR STACK CONTROL

In a slug wrapping machine, the slug after it enters the wrapper needs to be held from sides. This can be done either by means of soft pressure belts that gently press the stack so that the biscuits donot tip over, or by means of chain mounted tuckers that press the wrapper in the empty space between the stacks. Both the methods have their relative advantages. Logipac 51E allows you to select any of these two options for any size change.

» SPLICING OF WRAPPER

Logipac 51E has the feature of automatic splicing of wrapper as its roll finishes, thereby reducing the downtime for roll change.

HIGHLIGHT

» Fastest biscuit size change in its class

» No size change parts needed

» ‘No biscuit no pack’ interlock

» Discharge with 2 in 1 option: Dual belt/chain system

» 7 servo\PLC system with touch screen HMI

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.